Hybrid 3D Printing Used By Researchers To Create Cartilage Replacement

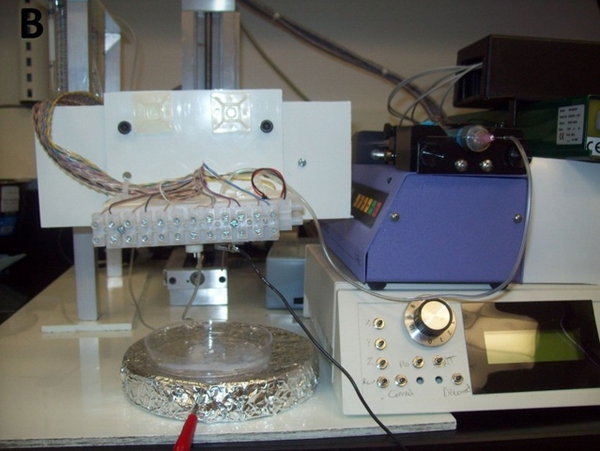

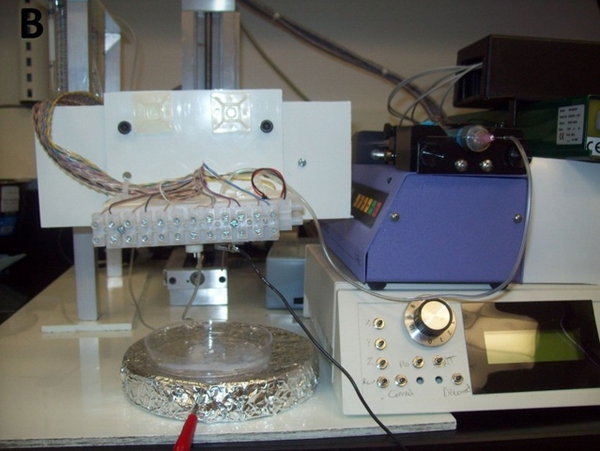

An inkjet printer that creates living tissue? Sounds like something out of a sci-fi flick, right? In fact, Wake Forest researchers have developed a process that combines medical inkjet printing—bioprinting—with electrospinning—a process that creates synthetic, polymer-based materials used for implants and wound dressing—to create cartilage implants. The implants may eventually be used to help injured patients regenerate their own cartilage. The study, recently published in the science journal Biofabrication, involved inserting the implants into mice for two, four and eight weeks, and garnered successful results.

“After eight weeks of implantation, the constructs appeared to have developed the structures and properties that are typical of elastic cartilage, demonstrating their potential for insertion into a patient,” said the Institute of Physics, which publishes Biofabrication.

Scientists hope the same method could allow future medics to create cartilage specific to an individual patient’s needs. An MRI scan could be used to create a blueprint of a patient’s body part, and matching cartilage could be created using the 3D printer.

“This is a proof-of-concept study and illustrates that a combination of materials and fabrication methods generates durable implantable constructs,” James Yoo, a professor at the Wake Forest Institute for Regenerative Medicine and one of the paper’s authors, told the BBC.

As injured cartilage has almost no ability to regrow itself, surgeons must currently treat cartilage injuries by removing small pieces of torn tissue or creating microscopic grafts to try and minimize pain. They are not able, however, to regenerate the tissue’s cushioning or lubricating qualities. Therefore, cartilage injuries and diseases most generally result in joint replacement surgery. The new procedure could eventually eliminate such invasive procedures.